🔧 A2L Refrigerant & Dissipation Control Integration with SmartZone Systems

When using A2L refrigerants (like R-454B), HVAC systems must include safety features to detect leaks and prevent refrigerant accumulation in occupied spaces. This is typically handled by an A2L dissipation or mitigation board, which monitors refrigerant sensors and triggers a response if a leak is detected.

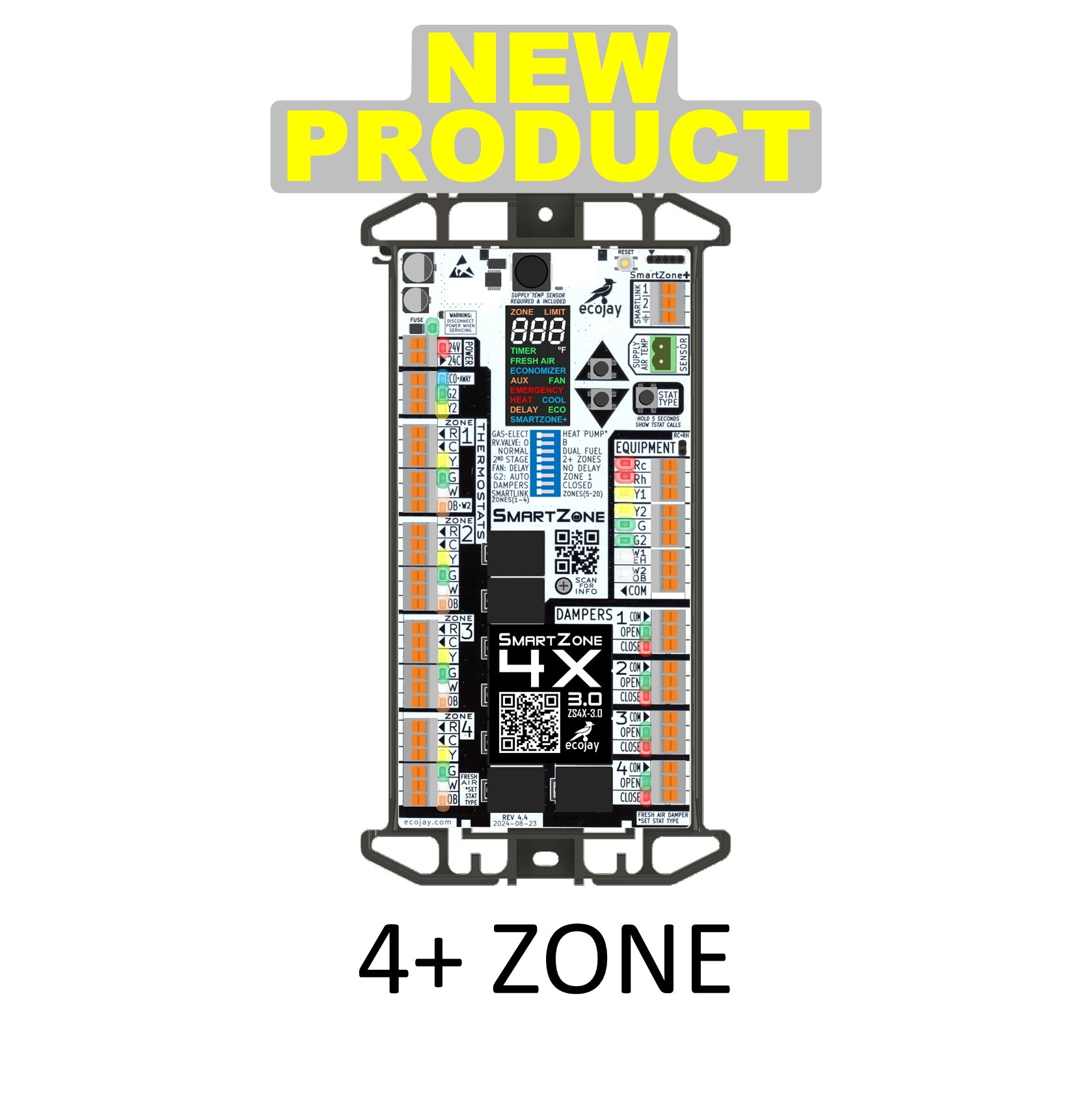

In systems with zone control (such as Ecojay’s SmartZone-4X and 3X 3.0), integrating this safety feature becomes critical. If a leak is detected, the mitigation board sends a signal that must:

Shut off the compressor

Force the indoor blower fan on

Open all zone dampers to allow air circulation through the entire duct system and prevent refrigerant from building up in unused zones

To achieve this, the dissipation board is typically wired to the zone panel’s A2L input, or through a relay that triggers an override mode. This ensures SmartZone responds to the leak event by energizing the blower and opening all dampers simultaneously, regardless of normal zone calls.

This integration ensures compliance with UL 60335-2-40 Ed. 4 requirements and helps protect occupants while maintaining zoning functionality.

PRE ORDER - A2L mitigation compliant SmartZone

June 20, 2025 - NOTE: SmartZone-4X 3.0 with version 24E firmware is only available upon request.

If you need this feature, use the COUPON CODE: A2L at checkout.

MORE about A2L and R-454B / R-32

In the HVAC industry, an A2L sensor is a gas detection sensor specifically designed to detect A2L-class refrigerants, which are mildly flammable under ASHRAE Standard 34. These sensors are increasingly important due to the growing adoption of low-GWP (Global Warming Potential) refrigerants like R-32 and R-454B, which fall into the A2L category.

🔍 What is an A2L refrigerant?

A2L = Lower flammability (Class 2L)

"A" = Low toxicity

"2L" = Mildly flammable

Common A2L refrigerants: R-32, R-454B, R-452B

Used as environmentally friendlier alternatives to older high-GWP refrigerants like R-410A.

🛠️ What is an A2L sensor?

An A2L sensor detects leaks of these mildly flammable refrigerants and is used to enhance safety in mechanical rooms, refrigerant piping chases, and occupied spaces.

⚡ How is it wired?

A2L sensors can vary by manufacturer, but typically they are hardwired and may support analog, digital, or relay output signals. Here's a general breakdown:

1. Power Supply

Usually 24V AC or DC

Two terminals: Power (V+) and Ground (GND)

2. Signal Output (depends on sensor type)

Analog: 4–20 mA or 0–10V output proportional to refrigerant concentration

Relay Contacts: Dry contact output to trigger alarms, shutoff valves, or ventilation

Digital Communication: Some may use Modbus RTU or BACnet MS/TP

3. Wiring Summary (example for a relay-output model):

TerminalFunction124V Power (+)224V Ground (-)3Relay Common (C)4Relay Normally Open (NO)5Relay Normally Closed (NC)6–7Optional: Analog output or comm

📌 Installation Notes

Typically installed near the floor (A2Ls are heavier than air)

Should be located near potential leak sources (e.g., indoor coils, piping)

Must be calibrated periodically

Often required by code (e.g., UL 60335-2-40 Ed.4) when using A2L refrigerants in occupied spaces

Summary of UL 60335-2-40 Ed. 4 – A2L Refrigerant Focus

🧯 1. Leak Detection Requirement

Systems with A2L refrigerants in occupied spaces may require a refrigerant detection system (RDS).

Trigger threshold: RDS must activate well before reaching 25% of the Lower Flammability Limit (LFL).

💨 2. Mitigation Requirements

When a leak is detected:

Compressor must shut off immediately to stop further refrigerant release.

Indoor blower fan must activate to dilute leaked refrigerant and prevent dangerous concentrations.

These functions are typically managed by a Mitigation Control Board (MCB) or A2L dissipation board.

📏 3. Charge Limitations

Systems using A2Ls must stay within specific refrigerant charge limits, based on room size and system type.

If charge exceeds certain thresholds, leak detection and mitigation becomes mandatory.

🛠️ 4. Installation Location Rules

Indoor units must be installed with proper clearances and venting.

Leak sensors are required when system components are in confined or enclosed spaces.

⚠️ 5. Safety Shutoff and Lockout

After a leak is detected and mitigated, the system may require manual reset or technician intervention before restarting.

🧪 6. Sensor Calibration & Fault Handling

Sensors must be calibrated, tested, and fail-safe (e.g., if the sensor fails, the system must behave safely).

Systems must respond safely to a sensor fault or power failure—typically by shutting down refrigerant flow.

✅ Purpose of These Requirements

Prevent accumulation of flammable refrigerant concentrations

Ensure early detection and ventilation

Comply with evolving refrigerant use in line with environmental regulations (e.g., AIM Act, CARB)

💡 In Practice (American Standard Example):

American Standard units using R-454B are UL 60335-2-40 Ed. 4 compliant.

These units come factory-equipped with an RDS and A2L dissipation board that automatically:

Shuts off compressor

Runs the blower fan

Issues alarms if necessary

LEGACY SmartZone ZONING SYSTEMS & A2L

Some zoning systems, however, do not have an A2L input (legacy systems including SmartZone 2.0). Some may need to be upgraded / replaced when installing new HVAC equipment but not all of them.

With SmartZone-4X 2.0, the “eco mode” input can be used but zone 1 will not be available, therefore rendering it a 3 zone board instead of 4.