UPDATE: March 2017 - NEW Dampers available now. TAKE-OFF ROUND, INSERT ROUND & RECTANGLE Dampers all available now ... scroll down to see all damper models. OR click here.

Some older zone control panels have only two connectors for damper wiring (common & power-close). These were designed when predominately 2-wire (spring open) dampers were used for zoning. In recent years, 3-wire (power-open, power-close) dampers have become more common because of their low power consumption and higher reliability. You might think you have to upgrade your zoning panel to accommodate for these preferable 3-wire dampers... not with Ecojay dampers and belimo actuators. The wiring diagram below shows how to connect the Ecojay Power Damper to an older zone panel that is only designed to work with 2-wire dampers.

If you are planing to replace the zone controller with SmartZone, this diagram is NOT necessary.

If you have any questions, call or email us.

Flange & adhesive gasket make install easier than any other damper, Industry-leading quality & highest reliability, Belimo Motor, Full-seal gasket blade, Super-Heavy Duty, Ribs for easy flex duct attachment, One crimped end for easy solid duct attachment, 5 Year replacement warranty

NOTE: All dampers subject to a 10% restocking fee.

4", 5", 6", 7", 8", 9", 10" ROUND Diameter Dampers

12” & 14” Diameter insert dampers require additional hole to be drilled in duct opposite damper. (grommet included to insert shaft)

FEATURES:

Industry-leading quality & highest reliability, Belimo Motor, Full-seal gasket blade, makes mounting in any round duct easy with these super-heavy duty retro-fit slip-in dampers

NOTE: All dampers subject to a 10% restocking fee.

PRO- GRADE SPRING OPEN or CLOSE DAMPER

SELECT Spring DIRECTION:

- SPRING OPEN, POWER Close Motor or

- SPRING CLOSE, Power Open Motor.

Full-seal gasket blade, BEST spring damper available. Replace Honeywell ARD & any other 24V spring dampers.

NOTE: All dampers subject to a 10% restocking fee

6" X 6" thru 24" X 24"

SUPER Heavy-Duty

Aluminum rectangular damper w/ Ecojay by Belimo motor

Built to stand up to use and abuse

ATTENTION:

Due to delays receiving raw materials, the shipping time on these custom rectangular dampers has been extended: UP TO 3 or 4 WEEKS

We are very sorry about this delay and will be back to normal shipping times by the end of the year. Please call us if you have any questions or concerns about your order.

SHIPPING TIME: UP TO 3 or 4 Weeks

(because they are custom made to order)

RETURNS for rectangular dampers require 25% restocking fee because they are custom made to order... please be sure you order the correct size.

NOTE: The motor will always be mounted on the “HEIGHT” side

Round gasket-ed blade, weight-arm style pressure relief (Bypass) damper.

NOTE: All dampers subject to a 10% restocking fee.

Includes:

(1) Power Zone Damper

(1) Static Air Pressure Switch

Combined, these can be used as the most effective and reliable means of air pressure relief (BYPASS) for any zoning system.

NOTE: All dampers subject to a 10% restocking fee.

Static Pressure Controlled Bypass Switch

Use with ANY 3-wire (Power Open/Close) Damper - Sold Separatly:

Click here for 3-wire Power Damper

Automatically controls damper for accurate and quiet pressure relief necessary in most zone control applications.

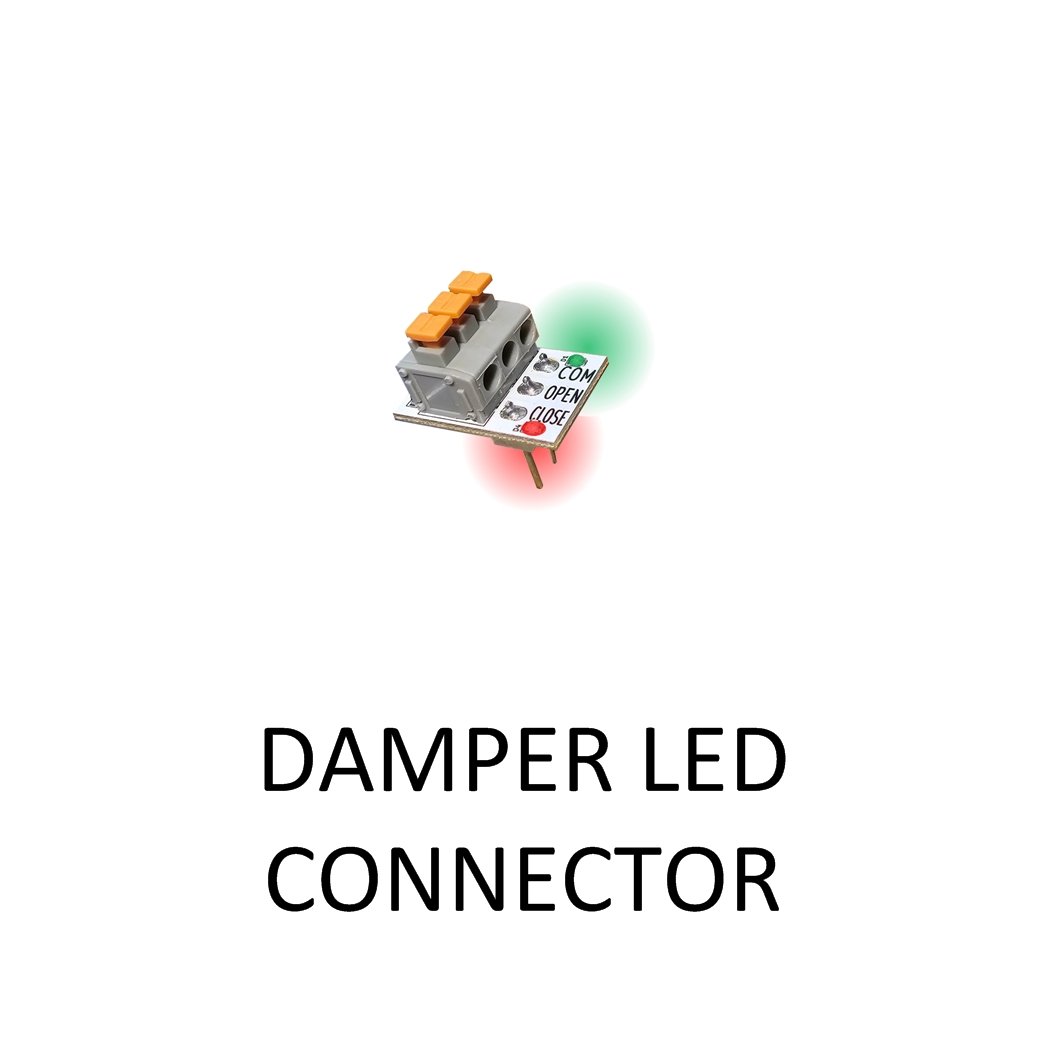

LED screwless wiring terminal for APDM damper motor that includes color LEDs to indicate open and close position.

GREEN = OPEN

RED = CLOSED

Available in 2- Pack and 4- Pack

$12.99 for 2

$19.99 for 4

When more than one damper per zone is needed, this adapter can be used to make wiring easy and organized.

4", 5", 6", 7", 8", 9", 10", 12", 14", 16", 18" Available

FEATURES:

Industry-leading quality & highest reliability, Belimo Motor, Full-seal gasket blade, Super-Heavy Duty, Ribs for easy flex duct attachment, One crimped end for easy solid duct attachment, 5 Year replacement warranty.

NOTE: All dampers subject to a 10% restocking fee.